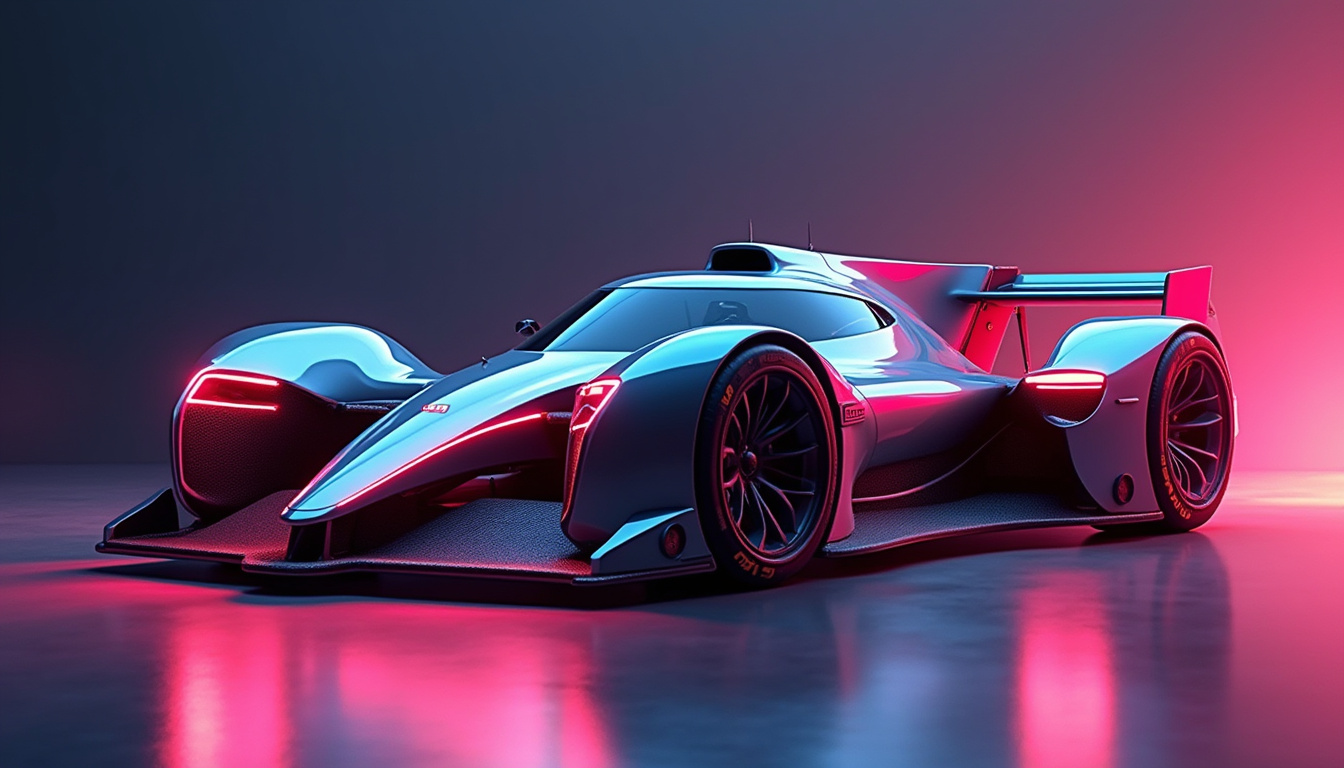

In the fiercely competitive world of high-performance vehicle engineering, prototype aerodynamic optimization is key. At ElectraSpeed, we blend CAD design, CNC machining, and CAM workflows. We build parts that lower drag and boost downforce. These parts push the limits of speed, efficiency, and stability, and they help advance hybrid propulsion motorcycles and more.

The CNC Workflow: From CAD to CAM to Track-Ready Part

Prototype aerodynamic optimization starts in the digital studio. Engineers use CAD software to design airflow-efficient shapes. They plan each detail with words and numbers close together. The shapes follow rules such as laminar flow, pressure balance, and vortex control. Our team adds stress analysis and checks machining tolerances. This care helps parts handle forces without losing their form.

When the CAD design matures, it moves into CAM software. Here, toolpaths are made as short, direct steps. CNC machines follow these steps exactly. Machining settings—like feed rate, spindle speed, and tool engagement—are set to keep parts precise. Even when machining aluminum billets or carbon fiber composites, dimensions stay accurate to within microns.

ElectraSpeed’s CNC Machining Process Highlights:

- Importing precise CAD geometries: We bring in models using STEP, IGES, and SolidWorks files.

- Generating adaptive toolpaths: Our software creates clear paths for complex 3D surfaces.

- Implementing high-tolerance machining: We keep errors within ±0.01 mm for the best fit.

- Material selection and secure fixturing: We fix materials tightly to cut vibration and save strength.

- Post-machining quality control: Laser scanning and CMM inspections check that parts match the design.

Hybrid Propulsion Systems and Aerodynamic Synergy

Modern motorcycles use hybrid propulsion systems that need small, lightweight, and aerodynamic housings. Prototype aerodynamic optimization keeps airflow smooth and drag low. At ElectraSpeed, engineers work hand in hand with propulsion experts. They design cooling channels and streamline bodywork. This shared effort brings all parts together.

Billet aluminum and carbon fiber work as a pair. They improve strength and help manage heat. We run CFD simulations alongside physical prototypes. This blend finds aerodynamic issues early. Then, quick design changes bring the idea closer to a race-ready, eco-friendly motorcycle.

High-Tolerance Component Engineering for Performance Part Prototyping

Performance parts require tight control. Slight errors here can change vehicle dynamics. Our processes hold machining tolerances as close as ±0.005 mm for key spots. In aerodynamic parts, smooth surfaces keep drag low. We use micro-milling and bead blasting to perfect edges. Our skill with tough materials like treated alloys and carbon fiber creates race-ready aerodynamic modules.

ElectraSpeed’s Integrated Design-to-Prototype Protocol

- Conceptual Aerodynamic Modeling: We use top CAD and CFD tools to simulate airflow and spot drag hot spots.

- Material and Manufacturing Feasibility: We choose pieces like 6061-T6 billet aluminum and prepreg carbon fiber based on strength and ease of cutting.

- CAM Programming & Toolpath Optimization: We create detailed toolpaths for 5-axis CNC machines to match 3D shapes.

- Prototype Fabrication: We run milling, turning, and composite layup to build the part.

- Dimensional Validation: We confirm dimensions with CMMs and laser scanners against the CAD model.

- Performance Testing & Feedback: We test in wind tunnels and on track to check aerodynamics.

- Iteration and Finalization: We refine the design with fresh data until it is ready for production.

This method joins clear digital planning with precise making to raise vehicle performance.

FAQs About Prototype Aerodynamic Optimization at ElectraSpeed

Q: What CNC tolerances can ElectraSpeed achieve for aerodynamic components?

A: We hit ±0.01 mm for regular parts. For key areas, we can reach ±0.005 mm.

Q: Which CAD file formats does ElectraSpeed support for aerodynamic prototyping?

A: We accept industry-standard formats like STEP, IGES, SolidWorks, CATIA, and Parasolid.

Q: Can ElectraSpeed handle both one-off prototypes and full production runs?

A: Yes. Our setup scales from a single prototype to medium production runs, always keeping quality high.

Advancing Aerodynamic Innovation with Authoritative Engineering Practices

ElectraSpeed follows best practices from the Machinist’s Handbook and guidelines from SAE International. Our hybrid CAD/CAM platform makes toolpath generation fast and clear. This efficiency cuts cycle times and holds part quality.

By uniting prototype aerodynamic optimization with high-tolerance CNC machining and modern materials, ElectraSpeed leads in high-performance vehicle design. We refine airflow around next-generation electric motorcycles and create custom performance parts. Our precise methods push motorsport and automotive innovation forward.

Meta Description: Discover how ElectraSpeed’s prototype aerodynamic optimization and precise CNC machining drive advances in high-performance vehicle design.

Keywords: prototype aerodynamic optimization, CNC machining tolerance, CAD to CAM workflow, hybrid propulsion motorcycles, billet aluminum machining, carbon fiber composites, aerodynamic prototype parts, high-tolerance engineering

ElectraSpeed is an advanced prototyping and engineering company specializing in CNC machining, CAD/CAM development, and hybrid propulsion innovation for the motorsport and automotive industries.

By merging precision engineering with digital design, we help builders, manufacturers, and racing teams turn ambitious concepts into race-ready reality.

Visit Electraspeed to explore our projects and engineering capabilities.

No Comments.