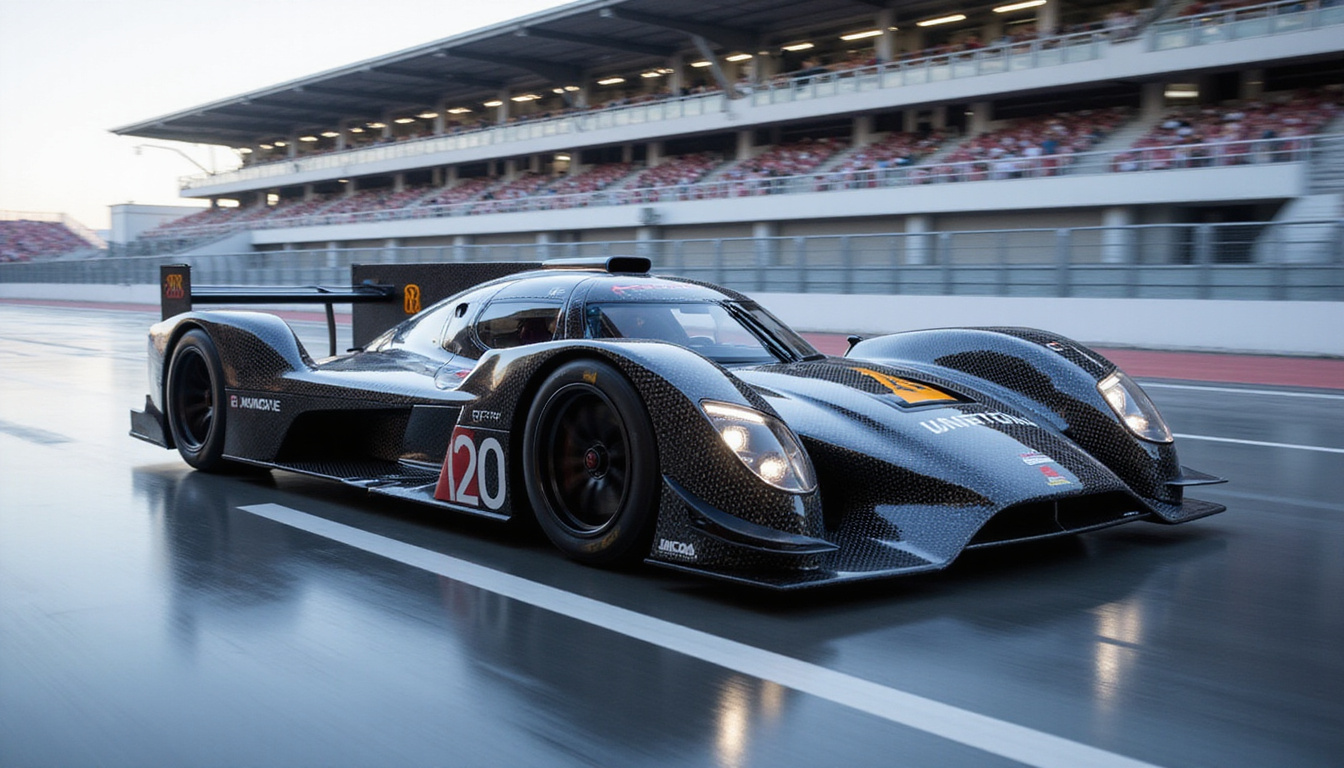

In motorsport, racecar design demands precise parts and smart materials. At ElectraSpeed, engineers blend creative ideas with fast CNC machining and direct CAD-to-CAM links. They join billet aluminum with carbon fiber to drive a quick shift from idea to a track-ready machine.

The CNC Workflow: From CAD to CAM to Track-Ready Prototype

Racecar design begins in a digital world. A powerful CAD system makes a 3D plan that shows every edge and curve. Engineers focus on smooth 3D surfaces while keeping the shape strong. This focus aids a fast airflow check early in the design.

After a CAD model is set, CAM software creates a clear plan for CNC machines. Here, CAD shapes turn into exact tool commands. The machine reads these commands with microns of tolerance. ElectraSpeed tests cut paths and fine-tunes tool contact to keep material stress very low.

Key process steps in our CAD-to-CAM conversion:

• Import and check CAD files (STEP, IGES) to trust every detail

• Edit 3D surfaces so curves and ribs become sharper

• Produce and test CAM tool paths to get a smooth finish

• Make G-code that lets multi-axis CNC mills do the work

• Run dry tests and change feeds/speeds to keep parts strong

This direct link from digital to real builds racecar parts with a clear blend of plan and performance.

High-Tolerance Component Engineering for Prototype Racecars

Exact machining tolerance matters in racing. Tolerance means the small gap allowed in part sizes. Tight gaps mean parts fit well, work better, and keep the car steady at speed.

ElectraSpeed holds tolerances to ±0.005 mm on key aluminum and composite parts. They use precise checking tools, like CMMs, to measure every detail. This care makes sure all parts fit tough racing rules.

Engineers also look at stress in materials to stop warping. They run FEA tests to check loads and heat shifts. This study helps both design tweaks and CNC settings.

Integrating Advanced Materials: Billet Aluminum and Carbon Fiber

Choosing the right material is key. Billet aluminum gives high strength with light weight. It also shapes nicely even with complex parts. Carbon fiber brings stiffness, quells vibration, and saves weight—ideal for body panels and suspension parts.

ElectraSpeed uses CNC precision to make aluminum frames that hold carbon fiber bodies. This mix builds a firmer frame with less mass. The result shows faster turns and quick starts.

Engineers also add surface treatments. They anodize aluminum for shine and rust protection. They smooth carbon fiber surfaces to cut drag and boost airflow.

Performance Part Prototyping: Rapid Iteration Through Precision Engineering

Rapid prototyping cuts the time from idea to race track. ElectraSpeed’s tight loop moves from CAD drawing to physical part in days. Fast tests, tweaks, and confirmations come before full production.

ElectraSpeed's Prototype Part Fabrication Workflow:

• Take the initial CAD model with all specs

• Run stress and thermal tests to match race conditions

• Create exact CAM tool paths for the chosen material

• Run CNC paths that hold the needed tight tolerance

• Inspect parts with CMMs and laser scanning to check fit

• Repeat design based on tests and airflow feedback

This close loop of design, toolpath, and test shapes a perfect part for race day.

FAQ Section

Q1: What CNC tolerances can ElectraSpeed hit in racecar parts?

A1: ElectraSpeed hits tolerances as tight as ±0.005 mm on aluminum and composites for perfect fits.

Q2: Which CAD file types work in ElectraSpeed’s workflow?

A2: They work with STEP, IGES, SolidWorks, and CATIA files. Engineers check and fix files for smooth 3D surfaces and CAM output.

Q3: Can ElectraSpeed run both one-off prototypes and small production runs?

A3: Yes, flexible CNC centers and clear CAM steps make both single fast prototypes and small batches possible.

Conclusion: Revolutionizing Racecar Design with Precision and Material Science

In racecar design, CAD/CAM steps, perfect tolerance, and modern materials push cars to peak speed. ElectraSpeed blends billet aluminum machining, carbon fiber work, and quick prototyping to help teams break limits.

By using up-to-date CNC tech and deep material skills, ElectraSpeed shifts a digital model to a race-winning machine in no time.

For more on aerodynamic tweaks and machining tips, see SAE International’s latest motorsport guidelines.

Meta Description:

Expert prototype racecar design using CNC precision, billet aluminum, carbon fiber, and smart CAD/CAM links for peak performance and speed.

Keywords:

prototype racecar design, CNC precision, billet aluminum parts, carbon fiber composites, CAD to CAM, aerodynamic optimization, racing prototype, high-tolerance machining.

ElectraSpeed is an advanced prototyping and engineering company specializing in CNC machining, CAD/CAM development, and hybrid propulsion innovation for the motorsport and automotive industries.

By merging precision engineering with digital design, we help builders, manufacturers, and racing teams turn ambitious concepts into race-ready reality.

Visit Electraspeed to explore our projects and engineering capabilities.

No Comments.