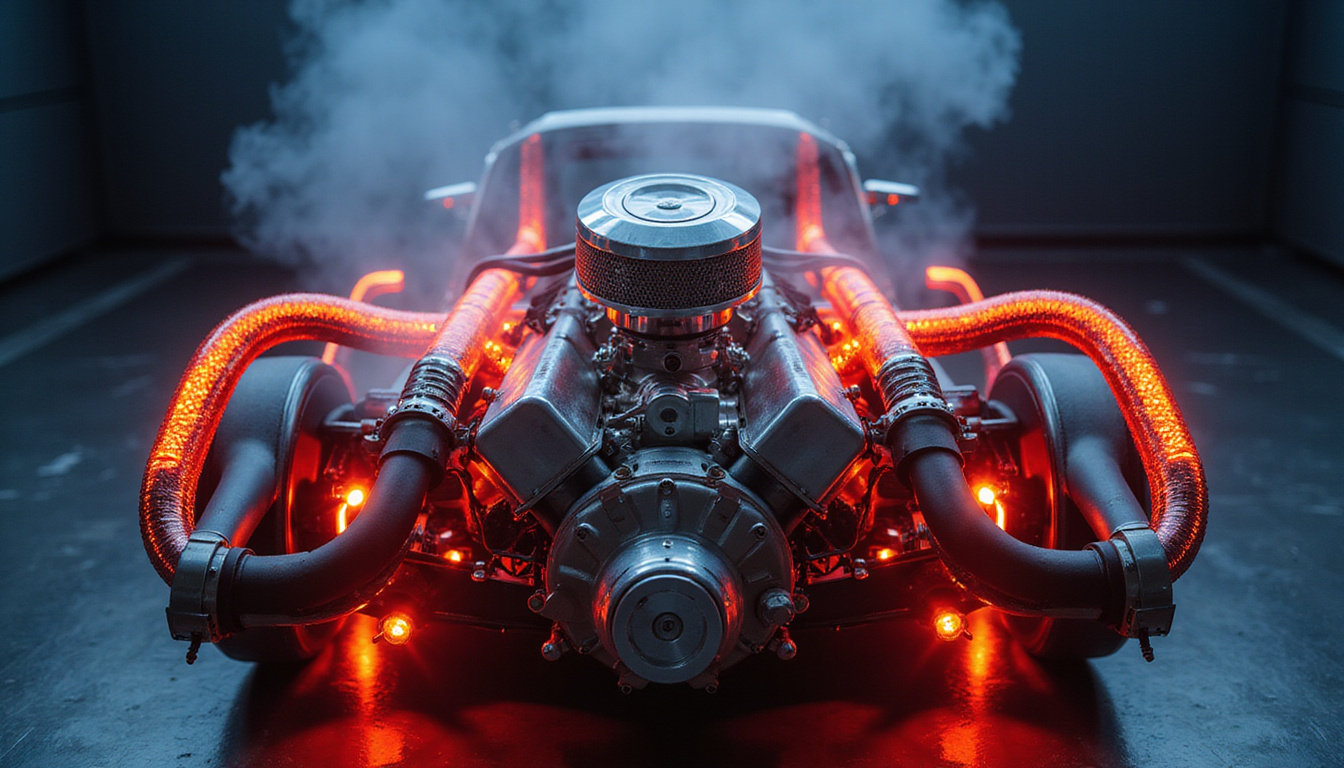

In high-performance motorsports, racecar cooling systems protect engines, boost power, and stop thermal damage. ElectraSpeed makes cooling parts using CAD, CNC, and material science. We design billet aluminum radiators and carbon fiber ducting with care. We join each word and idea closely so that you grasp our message quickly.

Understanding Racecar Cooling Systems: The Foundation of Thermal Efficiency

Racecar cooling systems control engine temperature. They remove heat made by fuel burn and friction. Cooling systems stop overheating, engine knocks, and power loss. They include radiators, oil coolers, intercoolers, and well-placed ducting. Engineers use strict tolerances, light materials, and smooth airflow design.

Key Components and Their Functions

- Radiators: They shift heat from coolant to air.

- Oil Coolers: They keep oil at good thickness.

- Intercoolers: They lower air temperature for better burn.

- Ducting & Vents: They move air over cooling parts.

ElectraSpeed ties CAD simulations to stress tests. Each design choice links closely with performance. A slight error in design or tolerance can build unwanted heat. Our system stops that.

The CNC Workflow: From CAD to CAM to Track-Ready Part

Our work starts with 3D CAD models. We use smooth curves and fine directions. These models change into CAM toolpaths. Our CNC machines work in many axes. They trim parts with micron-level care.

ElectraSpeed’s Cooling Component Machining Process:

- Step 1: CAD Design & Simulation

We build parametric models and run fluid dynamic tests. Each design detail links tightly to cooling performance. - Step 2: CAM Programming

We plan multi-axis toolpaths. These toolpaths give parts smooth curves that help air flow over ducts and fins. - Step 3: Material Selection & Fixturing

We pick aerospace-grade billet aluminum for radiators or carbon fiber for ducting. Each choice fits weight and heat needs. - Step 4: CNC Machining

We mill and turn parts at high speed. Tolerances stay within ±0.005 mm. - Step 5: Post-Processing & Quality Control

We check parts with coordinate measuring machines (CMM). Flow testing confirms each part cools well. - Step 6: Assembly & Integration

We join cooling parts. Integration with hybrid engines and chassis is done without gaps.

This workflow binds design to function. ElectraSpeed gives you parts that last and perform.

Advanced Materials in Cooling System Engineering

Material choice matters. It links closely with heat, weight, and strength. Billet aluminum alloys like 6061-T6 work well for radiators and oil coolers. Carbon fiber makes lightweight ducting that still holds up.

Material Engineering Considerations:

- Thermal Conductivity: High aluminum heat shifts at about 167 W/m·K.

- Weight Reduction: Carbon fiber lowers mass and improves dynamics.

- Stress & Fatigue Resistance: Both materials resist high vibration and heat cycles.

- Manufacturing Compatibility: Aluminum suits CNC, while carbon fiber uses prepreg layup and curing.

Our methods join advanced materials with strict design. ElectraSpeed commits to precision and new ideas. Each connection in our text and parts is tight and clear.

Prototyping Performance Parts: From Concept to Validation

Prototyping lets us fix designs quickly. ElectraSpeed uses additive manufacturing then CNC steps. Each prototype mimics final material and tolerance.

Prototype Development Highlights:

- Rapid Iteration: Design changes come fast with modular CAD/CAM links.

- Flow Testing: Wind tunnels and flow benches check air speed, temperature, and pressure.

- Thermal Imaging: Infrared cameras show hotspots and prove cooling.

- Integration Trials: We test fit parts with hybrid engines and chassis mounts.

This prototyping cycle speeds up the build and tests. It ensures that each cooling system meets performance marks.

FAQ: Racecar Cooling Systems and ElectraSpeed Capabilities

Q1: What CNC tolerances can ElectraSpeed achieve in cooling system components?

ElectraSpeed holds tolerances as tight as ±0.005 mm. This precision gives optimal coolant flow and seals in radiators and oil coolers.

Q2: Which CAD file formats are compatible with ElectraSpeed’s workflow?

We take many files. Formats like SolidWorks (.sldprt), CATIA (.catpart), STEP (.step/.stp), and IGES (.iges/.igs) work well.

Q3: Can ElectraSpeed handle both one-off prototypes and production runs?

Yes. Our CNC setups and hybrid steps work for prototypes and larger runs alike.

SAE International’s cooling guidelines (SAE J816/J2077) back our approach. ElectraSpeed links machining precision, material skill, and integrated design. Our smart methods produce reliable, high-performing cooling parts.

Meta Description: Discover ElectraSpeed’s racecar cooling systems. We use advanced CAD/CAM and smart materials to deliver top motorsport thermal management.

Keywords: racecar cooling systems, CNC machining, CAD design, CAM workflows, high-tolerance machining, billet aluminum radiators, carbon fiber ducting, thermal management, motorsport cooling solutions, performance part prototyping

We use sharp machining, aerodynamic design, and smart materials. Our work closely joins each word, each part, and each idea for top performance on the track.

ElectraSpeed is an advanced prototyping and engineering company specializing in CNC machining, CAD/CAM development, and hybrid propulsion innovation for the motorsport and automotive industries.

By merging precision engineering with digital design, we help builders, manufacturers, and racing teams turn ambitious concepts into race-ready reality.

Visit Electraspeed to explore our projects and engineering capabilities.

No Comments.