Research •//• Design •\\• Development

Innovative Prototyping & design for the automotive industry

Welcome to ElectraSpeed, where precision engineering drives innovation.

Specializing in advanced CNC machining, CAD design, and CAM programming, we deliver expertly crafted solutions tailored to the motorsport and automotive industries.

From custom prototypes to high-performance components, our expertise and cutting-edge technology ensure unmatched quality and reliability. Trust ElectraSpeed to bring your vision to life with speed, accuracy, and a passion for performance.

PRODUCTS

Product evolution from zero to 1

DESIGN •//• ENGINEERING •\\• MOTORSPORTS

Reimagining the motorcycle propulsion

NExt Generation Hybrid drives for motorcycles

With our revolutionary hybrid drive technology, you can now effortlessly add the power of overdrive to your motorcycle without the hassle of changing the gearing in the transmission.

Imagine the exhilarating feeling of effortlessly cruising on the highway with the wind in your hair and your machine gliding effortlessly ahead.

Our hybrid drive system takes motorcycle customization to a whole new level, allowing you to optimize your ride for speed and performance without any complicated modifications. Say goodbye to the days of tinkering with your bike's inner workings just to experience that extra burst of power. With our hybrid drive, you can replace the rear wheel and instantly enjoy the benefits of overdrive.

Experience the thrill of effortlessly overtaking others on the road, leaving them in the dust. Enjoy the enhanced acceleration, improved fuel efficiency, and smoother ride our hybrid drive technology provides. Leave your fellow riders in awe as you effortlessly conquer any terrain and easily conquer the open road.

Don't limit yourself to the standard ride. Upgrade your motorcycle to a whole new level with our hybrid drive system. Discover your machine's true potential and experience the ultimate freedom on two wheels. With our hybrid drive, the power to transform your ride is in your hands.

Unlock the full potential of your motorcycle and experience the benefits of overdrive today. Upgrade to our hybrid drive system and elevate your riding experience.

DESIGN •//• ENGINEERING •\\• MOTORSPORTS

Computational Fluid Dynamics (CFD) Simulations

advanced aerodynamic insights

At Electraspeed, when we're developing a CFD simulation for a motorcycle fender, we use advanced aerodynamic insights to focus on reducing drag and optimizing airflow around the front wheel. We apply sophisticated turbulence models, like RANS or hybrid models such as SAS or DDES, to simulate the aerodynamic performance of various fender designs. Our process involves creating a detailed 3D model of the fender, integrating it into the motorcycle’s overall geometry, and running simulations to identify areas where the fender might contribute to aerodynamic drag. We also explore near-wall treatments and boundary layer modeling to accurately predict flow separation points, which helps us refine the fender design to minimize turbulence and drag, ultimately enhancing the motorcycle's aerodynamic efficiency.

DESIGN •//• ENGINEERING •\\• MOTORSPORTS

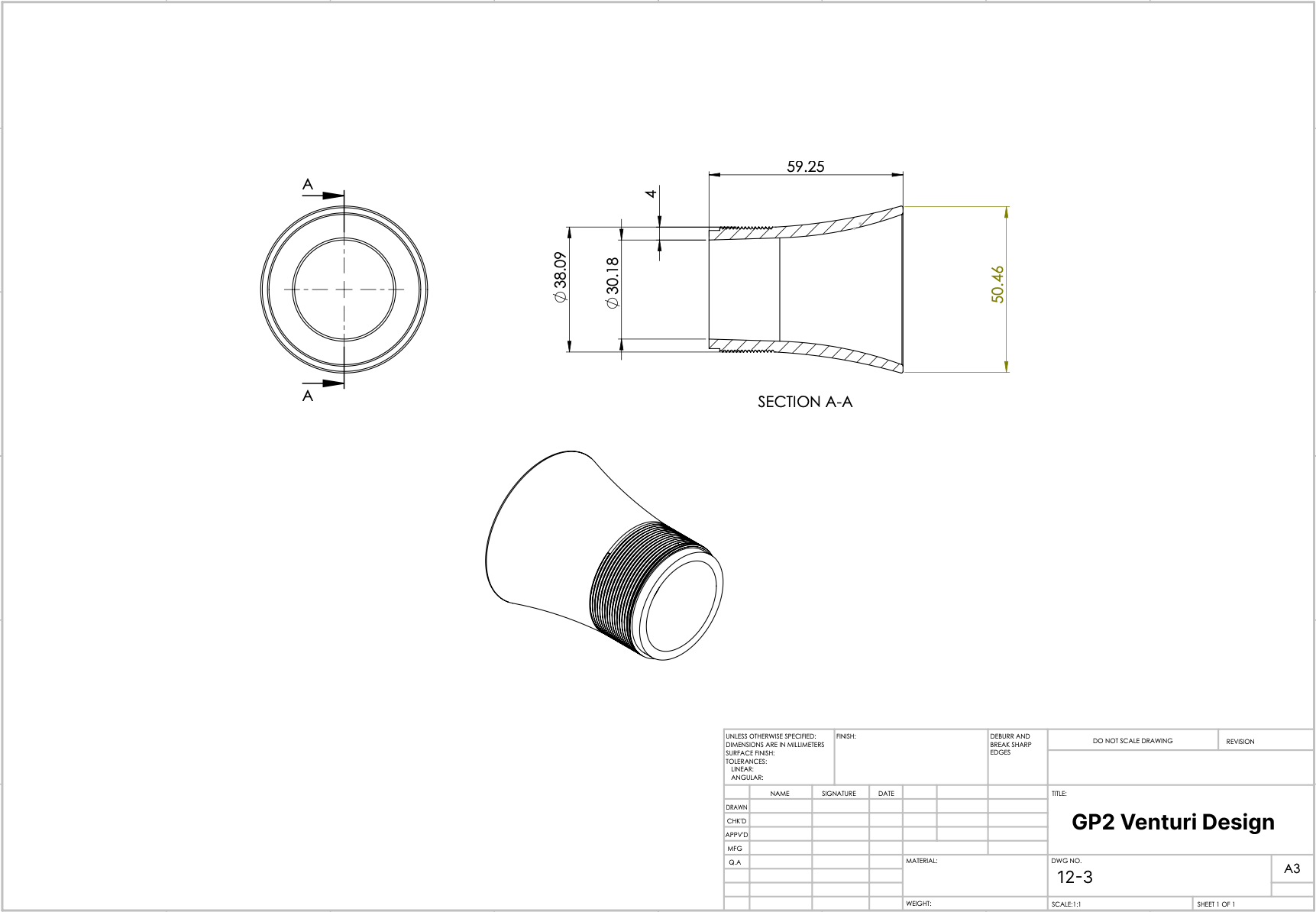

Making old engines breathe easy

High Performance

Venturi Design

Velocity stacks have evolved beyond just being used with carburetors. They are now commonly used in modern fuel-injected engines with throttle bodies. Since air and fuel are supplied separately to the engine, velocity stacks have replaced the ducting from the airbox and provide a cleaner, more laminar airflow. This clever tuning component is highly beneficial for supercars, sports cars, and even regular cars with high-revving engines.

DESIGN •//• ENGINEERING •\\• MOTORSPORTS

Reimagining the way we move.

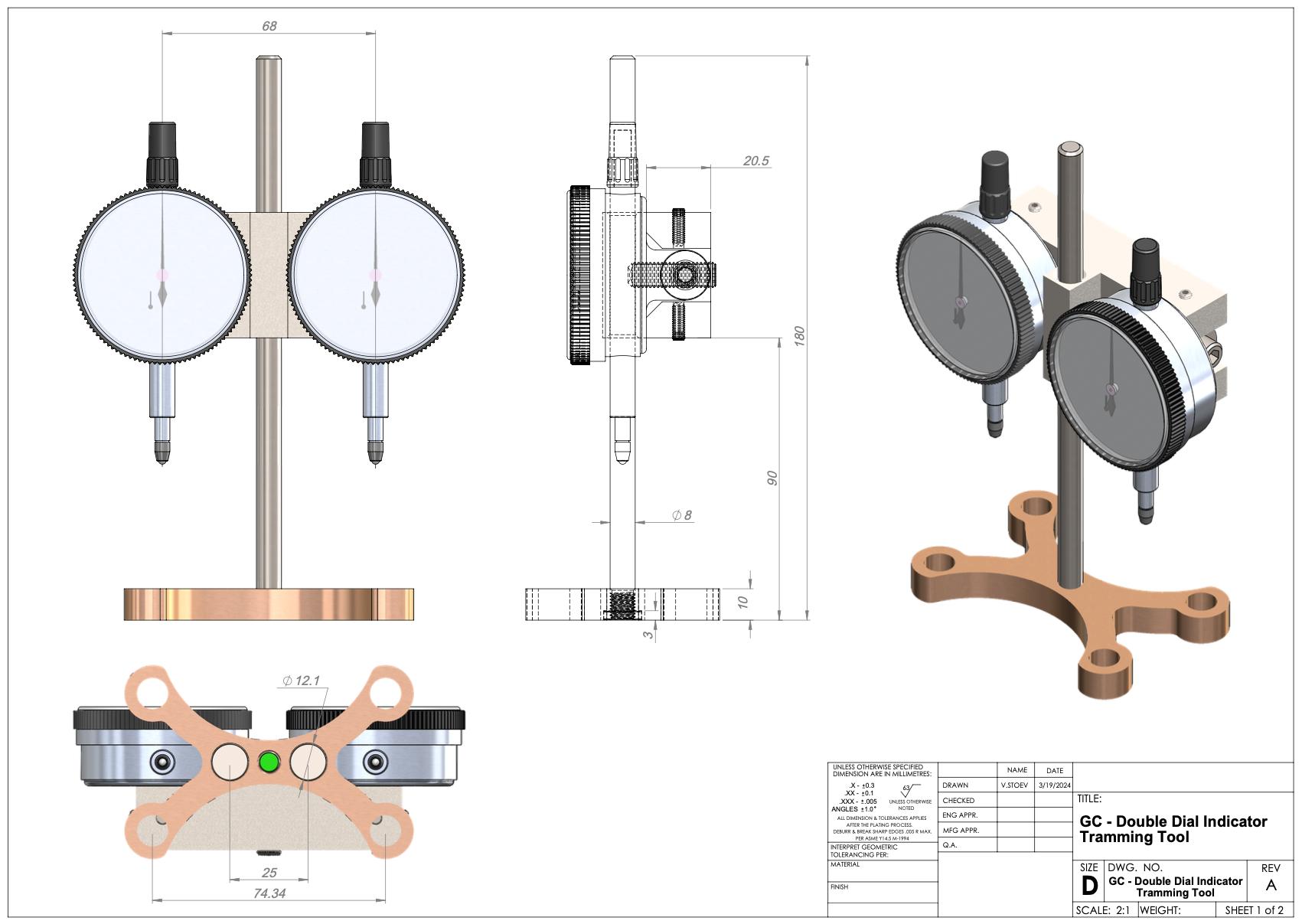

Precision Measuring Tools & Gauges

A dial indicator is one of the most essential tools you’ll find in any racer or rodder’s tool collection.

They’re used for everything from degreeing a cam to checking run-out on a disc-brake rotor (along with any number of tasks in between).

We are often asked to create custom one-off fixtures for measuring tools like dial indicators to facilitate service and make a technician's job easier. We are now releasing our designs to the public for purchase. These will soon be available.

//001

EMERGING

TECHNOLOGY

//002

PRODUCT

DESIGN

//003

PRODUCT

ENGINEERING

Who we are

Our mission at Electraspeed is to design and develop custom prototype solutions for the automotive and aerospace industries. We have 30 years of design experience in conception, designing, and developing everything from micro worm gears to new electric motor tech.

We leverage our unique technical abilities to design custom tooling and fixturing for manufacturing, from product conception to production.

Why did we start ElectraSpeed?

ElectraSpeed was formed to address a specific need for a prototyping design solution that could cater to the unique technical requirements of product development. We realized that traditional design methods were not sufficient to fully comprehend the intricacies involved in the manufacturing process and how products function. Therefore, we set out to create a solution that could simplify the design process and provide a deeper understanding of the product development cycle.

Our approach to prototyping design is based on a thorough analysis of the product's intended use, characteristics, and limitations. We employ cutting-edge tools and techniques to simulate the product's performance and optimize its design for manufacturability. By doing so, we ensure that the final product is of the highest quality, meets all the required specifications, and is delivered on time.

At ElectraSpeed, we take pride in our ability to provide our clients with a comprehensive prototyping design solution that caters to their unique requirements. Our team of skilled professionals is dedicated to ensuring that every project we undertake is completed to the highest standards of quality, accuracy, and efficiency.

Services

- Prototyping from Zero -> 1 your one-stop-shop

- Full-service Machine Shop, including 3D CNC machining

- Custom design from your ideas, sketches, or existing layouts

- CAD file Conversions

- 3D Conceptual designs & presentations for presenting ideas to your customer

- Complete Prototype Services

- Welding & Fabrication

- Mechanical Design Services using Fusion360, SolidWorks, Alibre Design or Catia V5-6

- Reverse engineering of your existing parts and digital scanning

- Thermoform/Vac form packaging and mold design and build

- 3D Laser Scanning and Probing

Industries:

While we primarily work within the automotive and aerospace industries, we often work designing tooling, mold making, food & beverage, and energy.

Get in touch

Contact ElectraSpeed today to get your project started

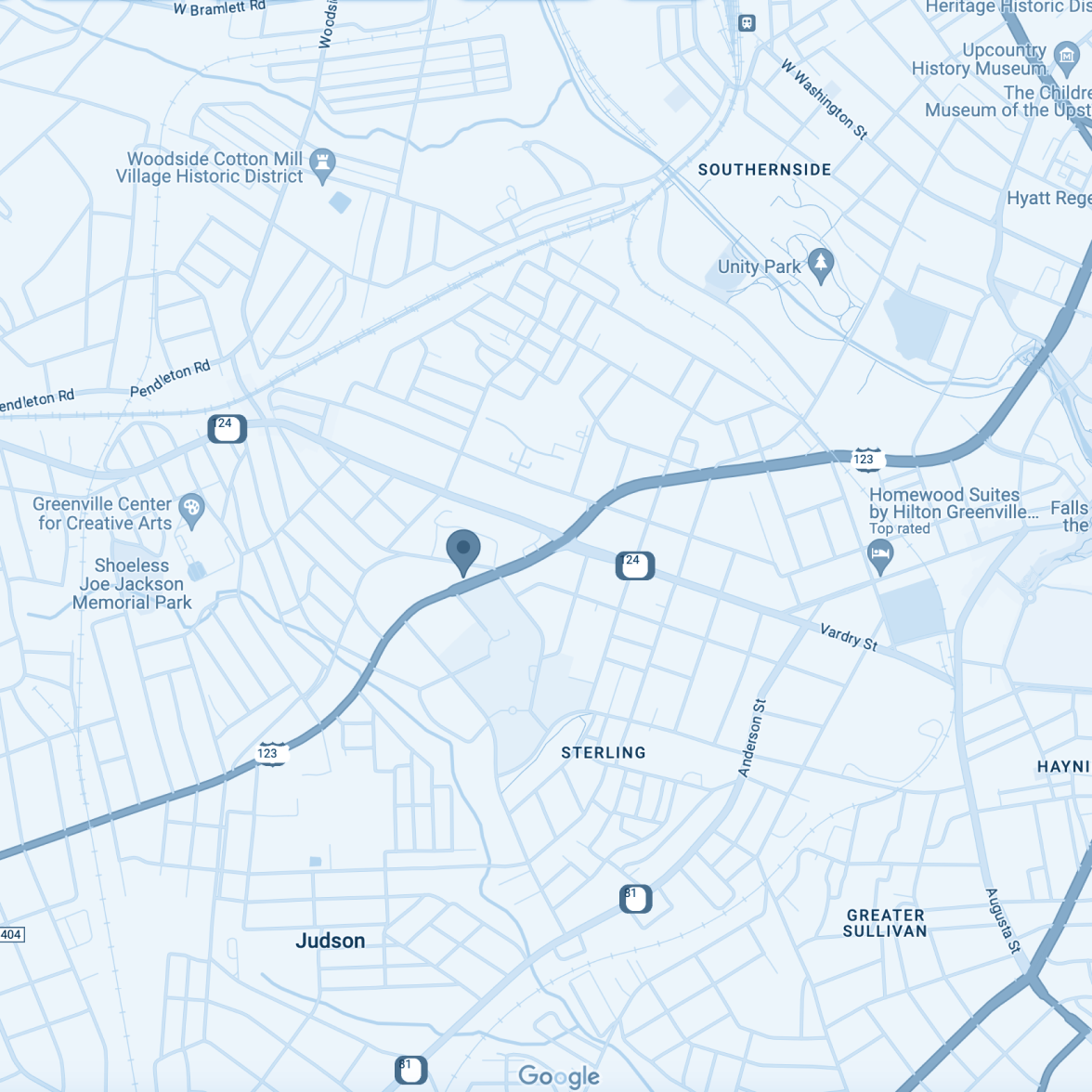

HQ - GREENVILLE SC

ElectraSpeed HQ

141 Traction St.

Greenville, SC 29644

USA

Contact

info@electraspeed.com

ElectraSpeed LLC

Research Design & Development for the Automotive Industry

141 Traction St.

Greenville, SC 29644

USA

Contact

info@electraspeed.com

Stay Informed

Subscribe to receive the latest updates on the great work happening at ElectraSpeed.

Products • Company • Services • News

© 2025 All Rights Reserved | Privacy Policy